No products in the basket.

Selenium Nanoparticle Applications

Introduction

Selenium is an essential trace element, vital for both human and livestock nutrition. It is a necessary dietary constituent of at least 25 human selenoproteins and enzymes containing selenocysteine. Due to its many health benefits selenium is a common additive to animal feeds and nutritional products. Additionally, as selenium is a semi-conductor and photoelectrically active it has more advanced applications such as xerography and solar cell assembly. More recently, Se Nanoparticles (SNP) have been used as a point-of-care test for the combined detection of anti-SARS-CoV-2 IgM and IgG in human serum and blood. Selenium rarely occurs in its elemental state and has typically been observed in its organic (selenomethionine, selenocysteine) or inorganic (selenate, selenide, selenite) forms.

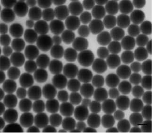

The development of uniform, monodisperse, nanometre sized selenium particles has gained commercial interest as such nanoparticles often display interesting electrical, optical, magnetic, and chemical properties in comparison to their bulk counterpart materials. The application of selenium nanoparticles (SeNPs) is of particular interest as it has been shown to enhance selenium’s biological and photoelectric properties. Furthermore, SeNPs are biocompatible and non-toxic, and exhibit low cytotoxicity compared to the counterparts, selenite (SeO32-) and selenate (SeO4–2).

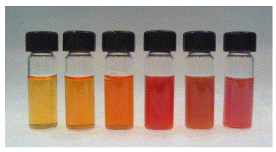

Fig. A. Photographic images of six size-distinguishable selenium colloids. From left to right, the images represent mean particle diameters of 20.0±6.1,70.9±9.1, 101.6±9.8, 146.1±23, 182.8±33.2, and 240.4±32.2 nm.

Fig. B. TEM image of uniform, monodisperse chemically synthesised selenium nanoparticles

Application Area 1: Increased bioavailability of Human Food/Animal Feed supplements

Nanosized particles may offer nutritional benefits such as enhanced absorption, bioavailability, antimicrobial activity, and excretion of the nanomaterials. The supplementation of animal nutrition products with SeNPs has shown highly promising outcomes when added to monogastric, ruminant and aquatic feeds (see Fig. 1. for applications of SeNPS in animal feeds). Nanoparticle delivery of minerals has been shown to be effective in improving feed conversion ratio, promote growth and development of muscle cells, improve the gut microbial environment, treat common parasitic disease such as coccidiosis and reduce mortality in poultry. Traditionally selenium is added to animal feeds in either its inorganic (selenite) or organic (seleno-methionine) form.

However, the use of selenium in its nanoparticle form in animal feed may be an attractive alternative as it does not need to be metabolised before being incorporated into selenoproteins and is thus more bioavailable than inorganic selenium. At present, there is a void of human SeNP supplementation trials and commercial products, however this is an area of highly promising research.

Application 2: A point-of-care test for the combined detection of anti-SARS-CoV-2 IgM and IgG in human serum and blood

Beginning in late 2019, a novel coronavirus, severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2), emerged in Wuhan, China. It induced an epidemic of severe pneumonia, now called coronavirus disease (COVID-19) which spread to other parts of China and later to the rest of the world. Early rapid detection is particularly important for COVID-19 epidemic prevention and control. Nucleic acid, gene sequencing and antibody (IgM/IgG) test results are recommended to be used as the basis for the diagnosis.

The combination nucleic acid and antibody detection can significantly improve the sensitivity of diagnosis for COVID-19 in the early phase of infection. The requirements of antibody detection are met by qualitative lateral flow immunoassays (LFIAs) with rapid and efficient characteristics. Selenium nanoparticles (SeNPs), as qualitative probes for LFIAs, have demonstrated higher levels of sensitivity and stability and are more economical to prepare than colloidal gold.

Application 3: Medical device

Nanoparticles have been widely investigated for various medical applications because of their high surface-to-volume ratio’s and their smaller size when compared with conventional micron-size particles. Their high surface area provides more sites for interacting with biological entities and for functionalization with other bioactive molecules such as anticancer and antibacterial drugs. Nanostructured selenium increases the surface area available to interact with and kill bacteria in addition to changing the surface morphology to ultimately inhibit the attachment of bacteria. Additionally, SeNPs have shown a sevenfold lower acute toxicity than sodium selenite in mice showing less prooxidative effects.

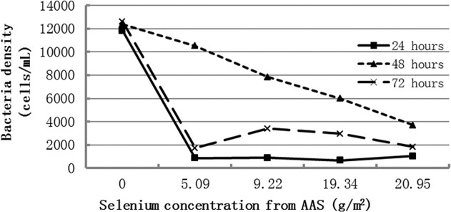

Biofilms are a common cause of persistent infections on medical devices as they are easy to form and difficult to treat. SeNPs may be coated on the surface of medical devices (such as those used for catheters, orthopaedic prostheses, contact lenses, prosthetic heart valves etc.) to prevent biofilm formation. A study by Wang et al. demonstrated that polycarbonate medical devices coated with SeNPs strongly inhibited the growth of S. aureus bacteria on the surface after 24 and 72 h by 91 and 73% respectively, when compared with uncoated polycarbonate surfaces. Importantly, this was achieved without using antibiotics but rather an element natural to the human body. Fig. 2 illustrates the decrease in S. aureus densities with increasing selenium concentration on the surface of polycarbonate.

Applications 4: Anticancer

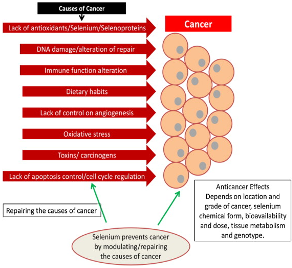

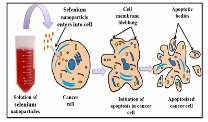

Selenium supplementation has been suggested as a powerful anticarcinogenic therapy. Large scale, double blind, randomised human intervention trials have shown that selenium supplementation of 200µg/day can lead to a non-significant reduction in all-cause mortality and significant reductions in total cancer mortality, and incidences of lung, colorectal, and prostate cancers. Although human intervention trials specifically using SeNPs are scarce, in vitro studies have observed that SeNPs functionalised with folic acid can induce apoptosis in cancer cell lines (breast cancer cell line (MCF-7). Additionally, SeNPs have been shown to cause cell shrinking and damage to prostate cancer cells during culture by causing cytotoxic activity. Due to their small size and large surface area supplemental SeNPs may increase selenium bioavailability and anticarcinogenic effects.

The mechanism of action of chemoprotective effects of selenium are not fully known however, several hypotheses have been proposed to explain selenium’s antitumorigenic activities. These may include protection against oxidative damage (via its function as a component of the antioxidant enzyme glutathione peroxidase); alterations in carcinogen metabolism; effects on the endocrine an immune systems; production of cytotoxic selenium metabolites, inhibition of protein synthesis; inhibition of specific enzymes; and stimulation of apoptosis.

Application 5: Solar cell

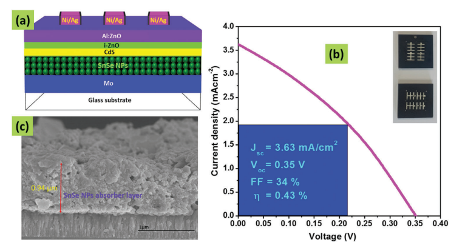

Selenium has several key features which make it a desirable solar cell component such as high sensitivity to light, ease of processing, and stability. This element shows high absorption coefficient and mobility, making it an attractive absorber for high bandgap thin film solar cells. Furthermore, the simplicity of a single element absorber (which significantly simplifies the deposition process) and intrinsic environmental stability enable the utilisation of selenium in extremely cheap and scalable solar cells. Selenium based solar cells have advantageous features over silicon and other emerging photovoltaic materials. They can be processed at significantly lower temperatures (below 200 °C) than silicon or CdTe processing temperatures. Selenium solar cells also show inherent stability to ambient conditions (e.g. humidity and oxygen). Furthermore, selenium is a p-type semiconductor, and studies have shown that that selenium has bipolar transport properties and can work as both a great transporter as well as a light absorber. A study by Pejjai et al. successfully incorporated tin monoselenide (SnSe) NPs into thin film solar cells which showed an efficiency of 0.43%. Fig. 4 represents a schematic and features of a SnSe Nps solar cell.

Application 6: Skin care products

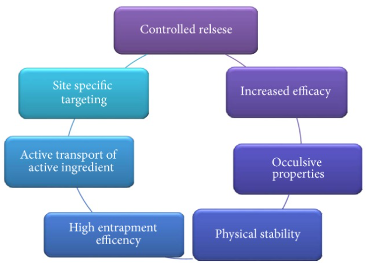

Nanotechnology is escalating in cosmeceuticals and nanocosmeceuticals used for skin, hair, nail, lip-care, and for conditions like wrinkles, photoaging, hyperpigmentation, dandruff and haircare damage are in widespread use. Due to their large surface area, novel nanocarriers such as SeNPs have advantages of enhanced skin penetration, controlled and sustained drug release, higher stability, solubility, and enhanced bioavailability as well as site specific targeting and high entrapment efficiency (see Fig. 5. for advantages of nanocosmeceuticals).

Selenoproteins play a key role in antioxidant defence and in maintaining a reduced cellular environment. UV radiations can include reactive oxygen species (ROS) which are key mediators of oxidative damage to skin. Repeated exposure to UV-A and UV-B can increase the risk of sunburn. Furthermore, oxidative stress (which is mainly driven by UV-A radiations) can result in premature aging, tanning and skin cancer. Selenium has been incorporated into sunscreen products in the form of nanoparticles as it has reduced toxicity in comparison to its more commonly used counterparts. The antioxidant activity of selenium enhances the activity of redox enzymes involved in free radical scavenging offering an effective alternative for the treatment of sunburn complications. The antioxidant effects of topical application of SeNPs may reduce oxidative stress by eliminating ROS and exhibiting an acidic pH (in the range of 4.2-5.6) which aids in the prevention of pathogenic bacterial colonisation, regulation of enzyme activity and maintenance of a moisture rich environment.

Application 7: Agricultural

The selenium content of soils varies greatly throughout the world and may range from 0.005 to 1200 µg g– although it is typically between 0.1 and 10 µg g–. One’s dietary selenium intake and thus plasma selenium levels are highly dependant on soil selenium content. The normalisation of selenium soil concentration may be achieved via the use of selenium containing fertilisers. Nanoscale selenium is of great interest as an additive to fertilisers. In comparison to organic and inorganic selenium compounds SeNPs do not dissolve in water and aqueous solutions and are not leached from the soil quickly. Se may be supplied from the soil to plants via nanoparticle surface gradual oxidation and oxide release to the soil solution.

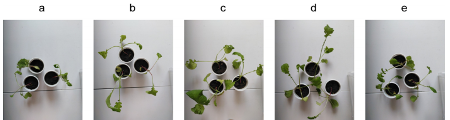

Studies have noted that soil fertilised with SeNPs lead to higher yields of fruit, rice, and tea leaves with a higher selenium content in the fruit. Furthermore, SeNPs added to fertiliser improved the growth cycle of blueberries which were of higher quality and had a longer storage period. (See Fig. 6 for impact of varying SeNP fertilisation concentrations on a radish plant). SeNPs have been shown to enhance the disease suppressing and anti-fungal abilities of plants. An additional benefit of using nano-fertilisers is that the large surface area and small size of the nanomaterials could allow for enhanced interaction and efficient uptake of selenium for crop fertilisation. This increase in uptake efficacy could lead to significant economic and environmental benefits.

Applications 8: Antidiabetic

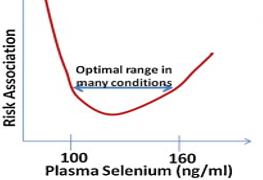

Although evidence on the effect of selenium on diabetes is somewhat lacking, studies have observed that diabetic patients have lower selenium status compared with controls. The prevalence of diabetes tends to be greater in men with low plasma selenium levels. Furthermore, a study noted that pregnant women with gestational diabetes had lower serum plasma levels compared to controls and significant negative correlations were found between serum selenium levels and CRP, total- and LDL-cholesterol levels. The antioxidant power of selenium may have a neutralising affect against oxidative stress which plays a major role in the pathogenesis of diabetes. Moreover, it has been hypothesised that selenium may influence glucose metabolism. Selenium supplementation has been shown to reduce the expression of inflammatory proteins such as interleukins and tumour necrosis factor in diabetic patients. The toxicity range for selenium is however very narrow and caution must be exerted to ensure beneficial therapeutic effects. Other research has suggested that the prevalence of diabetes is greater in those with a high plasma selenium status. At present, data available on the levels of plasma selenium and diabetes risk may be represented by a u-shaped graph (see Fig. 7). This implies that both low and high selenium intakes could influence the risk of diabetes and other clinical mortalities. Hence, although observational evidence suggests low selenium status may increase one’s risk of developing diabetes, further research is needed to explore a safe supplemental selenium intake to achieve beneficial therapeutic effects.

Applications 9: Anti-inflammatory

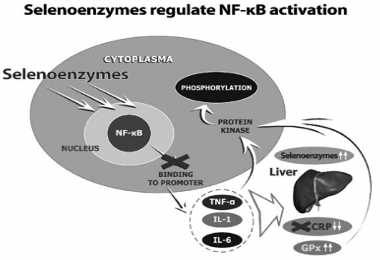

Selenium is a major antioxidant element acting via enzymes that catalyse redox reactions. These selenoproteins play a pivotal role in the antioxidant defence system of the cell. There is strong evidence to suggest that selenium may have an impact on the course and outcome of many inflammatory diseases (diabetes, celiac, HIV). Current data indicates that viral, bacterial, or stress induced inflammation may be variably influenced by selenium availability.

Decreased serum selenium levels have been observed in acute and chronic inflammatory states with high CRP values. Low selenium levels have also been noted in severe inflammatory response syndrome, which is marked by increased production of reactive oxygen species (ROS) by activated macrophages, induction of oxidative damage and tissue injury. The nuclear factor kappa-B (NF-KB) signalling pathway has been associated with enhanced inflammatory response and its activation has been significantly correlated with interleukin-6 and TNF-alpha production. Selenium is hypothesised to inhibit the activation of NF-KB by modulating gene expression. Supplementation with selenium in chronic inflammation restores the depleted hepatic and serum selenium levels by increasing selenoprotein biosynthesis. This effect leads to suppressed CRP production and thus attenuates the inflammatory response. Fig. 8 illustrates the relationship the relationship between selenoenzymes and the inflammatory response. Although there is currently a scarcity of published human trials investigating the anti-inflammatory effects of SeNP supplementation it is a promising area for future research as nanosized particles may have increased bioavailability than their larger counterparts and thus enhanced therapeutic effects.