Chromatography Technologies for Licensing

Giving Customers and Partners What They Want

What drives us in Glantreo is meeting and exceeding customers and partners requirements and expectations. So we did what any sensible company would do and asked our partners and customers what they wanted. And the result, not surprisingly, was that not all customers want the same. This could be due to relative size, the core competency of staff and company focus.

What we also found was that there were some partners who would like to make their own silica but currently don’t.

The reasons for them wanting to do so often included the following:

- To have strategic control over one of the key inputs into their chromatography products.

- To have more flexibility on product specifications and to potentially use this as means of differentiating product.

- To be able to control costs in the supply chain and potentially use price as a differentiator. Without the cost control price differentiation just results in margin erosion.

- To part hedge against disruptive technologies by leading and not following.

What do we offer?

Put simply we deliver the following:

- Validation lots of material so that you can satisfy yourself that the process is reproducible and that the material conforms to a marketable specification.

- Full Standard Operating Procedure for making the material.

- Full equipment setup and configuration required for making the material.

- Help and support through a Technology Transfer process to your site.

- On-going support as required if you decide to ‘tweak’ the process.

We understand that this will not work for all companies and that some can and will live with buying media and ‘taking their chances’. If however, some of the reasons given to us by our partners resonates with you then please feel free to contact us to discuss your requirements further.

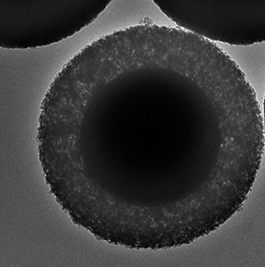

Monodisperse superficially porous silica

- Eiroshell™ Platform Technology

- Material produced is to a market driven specification

- Highly monodisperse

- Fully scalable from uHPLC to HPLC particle sizes

- Extremely tunable even at very small particles

Monodisperse fully porous silica

- SOLAS™ MONODENSE™ Platform Technology

- Material produced is to a market driven specification

- Highly monodisperse without classification

- Fully scalable from uHPLC to HPLC particle sizes

- Simple and efficient process

- High material yield