Glantreo’s magnetic silica particles are the product of many years working with silica particles and chemistries as well as the desire to deliver quality products for bio-analysis and separations.

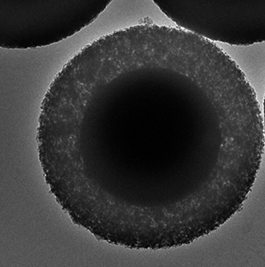

High magnetization (60 emu/g) and strong binding capacity give Glantreo’s magnetic silica particles a fast magnetic response (~5 secs) and shortens the time required for magnetic steps during isolation. Glantreo’s magnetic beads are completely spherical unlike other magnetic particles, and the smooth surface eliminates the carryover of impurities common to rough-surfaced beads. The uniform shape, size and smoothness of the particles enables DNA/RNA or protein purification to be performed with outstanding efficiency and reproducibility.

Our particles are available in 2 different particle sizes (500nm and 1000nm) in aqueous solution. The magnetite particles are coated with a thin layer of silica that allows functionalisation with amine and carboxyl groups as well as functionalisation with protein A. Our magnetic beads remain well suspended and dispersed for over 60 mins providing good handling and suitability for automation. Glantreo has been producing quality nanomaterial for 10 years in an ISO 9001 certified operation. Technical support is always at hand and a quick delivery of your order is assured.

Applications & Uses

❖ Magnetic DNA/RNA Purification

❖ Magnetic Protein Separation

❖ Magnetic Antibody Separation (IgG2)

❖ Magnetic Cell Isolation

❖ Concentration of product

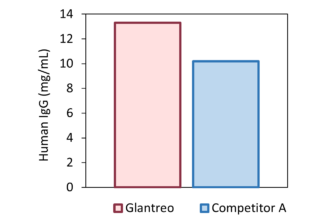

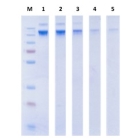

Figure 1: SDS-PAGE gel of Glantreo’s magnetic particles isolating IgG (left), and Comparison of protein binding efficiency of Glantreo Protein A functionalised magnetic bead with competitor (right)

Features & Benefits

Bead Size:

The average particle size of silica coated magnetic beads is 0.5-1 um and is the optimal size for attaching bio-molecules for research, purification and functional studies.

Shape and Uniformity:

Glantreo’s magnetic silica particles are completely spherical unlike most other magnetic beads. The average particle size distribution is uniform, and the smooth surface eliminates carryover of impurities common to rough-surfaced beads of competitors.

Batch to Batch Reproducibility:

Each batch is produced under strict quality controls. Errors that commonly occur during mass production are eliminated during the individual packaging process.

| Concentration (wt%) | Particle Size (nm) | Pack Size (ml) | Functionalisation |

|---|---|---|---|

| 2.5wt% | 500 | 25ML | Raw |

| 2.5wt% | 500 | 25ML | Amine |

| 2.5wt% | 500 | 25ML | Carboxyl |

| 2.5wt% | 1000 | 25ML | Raw |

| 2.5wt% | 1000 | 25ML | Amine |

| 2.5wt% | 1000 | 25ML | Carboxyl |

| 20mg per 1ml | 500 | 2ML | Protein A |

| 20mg per 1ml | 1000 | 2ML | Protein A |