Chromatography

Introduction

Next Generation Chromatography

Producing world-class uHPLC/HPLC columns from start to finish ourselves. R&D on innovative stationary phases, exceptional and reproducible bonding and packing along with method development.

Supporting our Global network of partners and distributors from our advanced facilities in Cork, Ireland.

Chromatography and making innovative materials for chromatography is the reason why Glantreo was setup in the first place. The company was initially founded to commercialise IP that was developed in University College Cork (UCC). This technology was further developed by Glantreo over a period of 18 months thereby creating a process for the manufacture of highly mono-dispersed silica particles for Chromatography. This IP was subsequently licensed to Supelco/Sigma Aldrich. The Glantreo Inside vision came to fruition when Supelco launched their Titan™ range of columns in 2013. Click here to read more.

Building on this success Glantreo set about doing a number of different activities.

Initially, we canvassed partners/customers and came to understand that some partners wanted better control over the silica media that was being used in their columns and therefore wanted to be able to make the silica themselves.

For others they just wanted to buy a product (silica, functionalised silica, or packed column) to further process or just sell to their customers. This being the case we therefore needed to be able to offer technologies for licensing and products for sale.

As a small agile company we pride ourselves on being able to respond to our Partners requirements. We have a wide range of HPLC column technologies. What we are looking for is long-term partnerships with companies who have the relationships with end users who could benefit from using our technologies. If you feel you can help add value then please contact us.

What makes us different from our competitors?

We make the columns ourselves from silica to packing and testing the columns. This end-to-end production allows us to:

→ differentiate ourselves at each stage in the production proces

→ have full control over the quality and reliability of the finished product

→ provide a premium product at an affordable price

→ be responsive to partners and customer demands

→ are not adversely effected by issues in global supply chains

How is it that we are Technically better than our competitors?

Apart from the above points related to us making the columns ourselves there are 4 key technical features that make our stationary phases different.

→ Monodispersivity

→ Monodensity

→ Controlled and Stable Porosity

→ Proprietary Bonding and Column Packing Procedures

↓ Monodispersivity

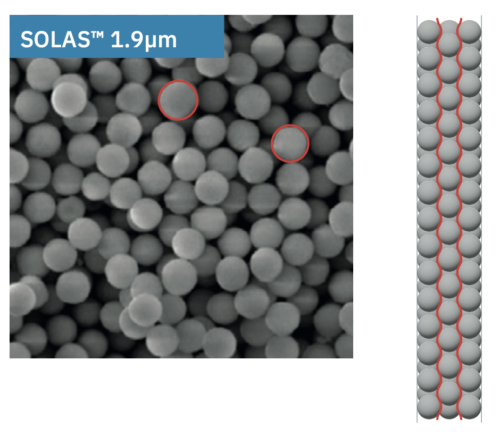

Glantreo’s patent protected silica manufacturing processes produce highly monodisperse particles. This is best illustrated in the images below where we compare our SOLASTM 1.9μm material with the a competitors, commercially available, 1.9μm material.

For those who prefer the numbers, the SOLAS material has a d90/d10 of 1.2 with the competitors being 1.5

↓ Monodensity

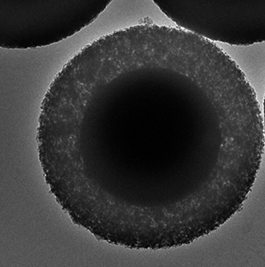

Glantreo have developed silica particles to be monodense. A lack of monodensity in underlying silica particles can cause issues for end users in the form of column instability and reproducibility over time. The images below illustrate mono density and in contrast what are often referred to as voids, holes, macro pores (or even doughnuts those in the silica manufacturing world).

↓ Controlled & Stable Porosity (CSP)

While pore size and pore volume are important, pore stability is also important, especially at larger pore sizes. This is why Glantreo have developed what we refer to as our Controlled and Stable Porosity (CSP) Technology. This technology has been scaled to over 1000Å pore sizes and can be used in both our SOLAS and EIROSHELL ranges.

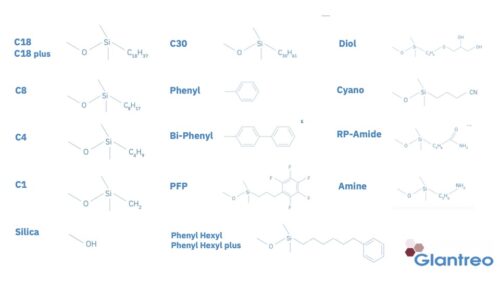

↓ Proprietary Bonding and Column Packing Procedures

Whilst having world-class silica as a starting point is vital, the ability to add functional groups and to pack the bonded silica into the appropriate column hardware is equally as important. Please see the below section on the different phases that we offer.

In addition to our optimised packing methods some key points to note regarding our packing capability are our Capacity (4 and 6 Multi Column Packing Stations give us high capacity), Hardware Quality (low Ra value on hardware finish) and Flexibility (extensive range of hardware and configurable frit choice). In essence, the chain is as strong as its weakest link with all our links being strong.

What will the Technical differences mean to our Customers?

What makes us different only matters if it matters to our partners and end users of our columns. Here’s some of the reasons why these technical differences will matter to our customers and partners.

→ Premium and world-class columns at an affordable price

Because we produce end to end we can control costs in ways that other companies who ‘buy in’ all or part of the end product. These savings, we pass on to our partners and customers and allow the end users to access world-class chromatography at an affordable price.

→ Column Performance:

Efficiency

Speed

Reproducibility

Stability & Longer Life

→ Continuous Support

With our in-house R&D team and highly skilled application scientists, we offer round-the-clock expertise for all Glantreo products, to all our customers. Whether it’s a troubleshooting inquiry, trainings, method development support or a new application, Glantreo offers free-of-cost telephonic and online support.